|

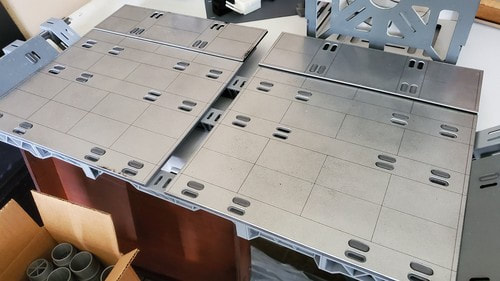

Other segments for the VSS Space Carrier 002 are being worked on. Some of these segments I have returned to finalize them and prepare them for 3D printing and laser cutting. There are some slight changes -- alterations, modifications, adjustments -- but for the most part the design remains consistent to what has been previously shown in this blog. Engine Compartment Round 2: The first round of posts for the engine room showed the intent for the design. Since then I've gone back to the engine room to finalize the assembly. What this means is I started to assemble the engine compartment virtually, as if the CAD drawings were completed. Using the CAD program SolidWorks I made an assembly for the beams -- the joists that will support the underside of the floor -- with all of the pegs that the joists will require. Then I made another assembly and attached the floor, which will be laser cut wood. I then made a 3rd assembly combining the previous two assemblies. I kept doing this, making a new assembly, until I was satisfied that how I assembled virtually in SoldiWorks will be exactly what I will expect for the physical model. I proofed everything: seeing how all the parts fit, double checked the clearances, taking into consideration the types of plastics and the way the parts will be made. Then I started the print. First, 3D print the joists/beams. Each component would take hours, some as much as 8 hours. To do half of the floor I would need three sets of these components. Next came the laser cutting step. First I laser cut the wood and the ABS sheets. For the styrene I wanted to paint it in two colors, black first, and a top coat of titanium. The idea is that I can use a low power laser to score a bit off the titanium exposing the black paint underneath. This will be good for doing small details, such as panel lines. I was about to do other little details, such as screws, but at the last moment I thought against it. The wood is sandwich between a layer of ABS, both at the top and bottom, and styrene at the very top. The styrene, being a very thin sheet, will help the floor have a very smooth surface. I didn't want the grain of the wood or the rough "dimple-like" surface of the ABS sheets to be visible as surface textures. Next:

Next up will be the other half of this floor. The joists are currently being 3D printed, and the laser cut parts are already done. After that will come the walls. At the same time I have started the assemblies for building the engine component that fits into the VSS itself. That part is a challenge all it's own. |

DioWarriorsLatest News blog thingy. Archives

May 2024

Categories |

RSS Feed

RSS Feed