|

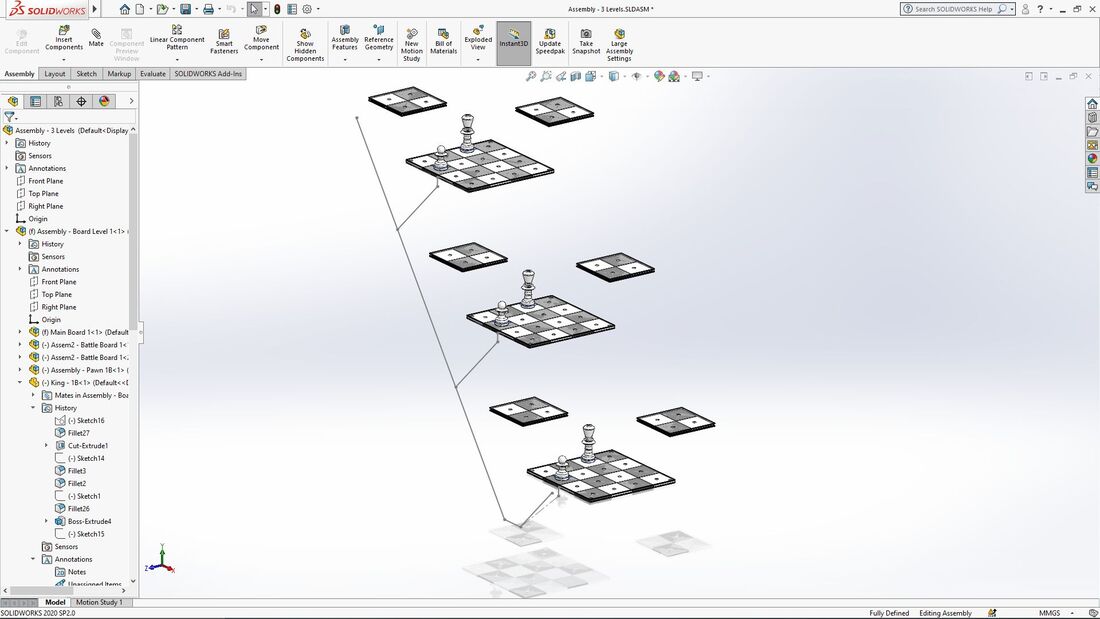

it's been in the back of my mind for a number of years to one day make my own Tri-Dimensional Star Trek style Chess set. I've always wanted to make my own set and I'm also a big Star Trek fan, so with both 3D Printers and laser cutters available, I decided that now is the time to actually do it. The first step was to do research. Firstly into the Star Trek style tri-dimensional Chess and then to real world Chess. There are standards for the game, for both tournament purposes and normal consumer. The tournament sizes are larger -- larger squares and pieces -- so for this project I went with the slightly smaller consumer size. The Chess board itself will be much larger than a traditional Chess board. Don't want to make something too big or I really won't have the space to display it. The battle plan will be to 3D print the Chess pieces and laser cut the boards. The pieces themselves will be designed to hold a magnet to keep them secured to the board. The pieces will also be hollow to reduce the amount of plastic and also reduce the time to print.

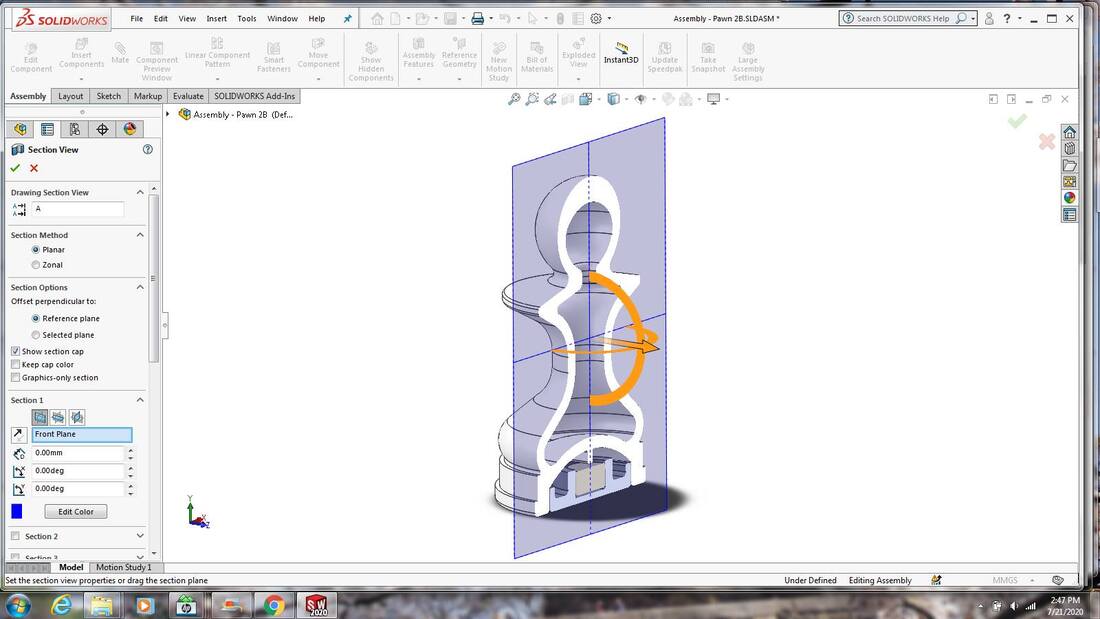

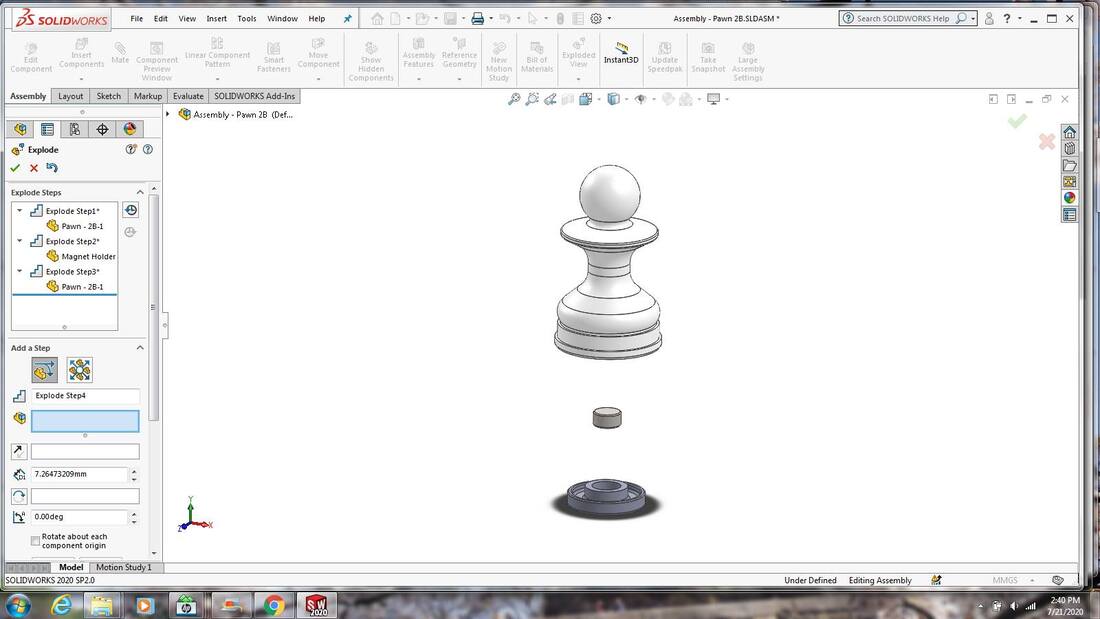

Pawn: Being the smallest piece, the pawn is a good test model. I think I'll go with this look for the rest of the pieces. When my family lived in Singapore, my father bought a Chess set and I always liked the way the pawns looked. So my pawns are inspired from that set. Concerning the color, the Chess pieces might remain the traditional black/white, but I am unsure at the moment if they will be painted some other color. In various Star Trek series the Chess pieces are either silver/gold, or black/white. So what I think I'll do is print a few pawns and paint them with different colors. I'll include progress pictures in the upcoming blogs.

Folks tend to ask me quite often which of the three laser cutters -- GlowForge, Flux BeamBox, Flux Beamo -- I like and what are their differences. So in Facebook I have been writing comparison posts, but the posts eventually get pushed down and forgotten. So I decided to copy/paste my comparison write-ups here where I can keep them current and updated. This "little" article may have some repetition. I will return to it and will try to consolidate all the topics. But until then, enjoy! Brief Thoughts: As both an owner of a Glowforge (by Glowforge) and Beambox and Beamo (both by Flux), I tend to do comparisons for myself as I migrate work between these machines. These are laser cutters capable of either cutting or engraving on a vast number of different materials. I like both brands -- Glowforge and FLUX Inc. Both machines will do amazing work laser cutting and engraving. Some things with the Glowforge is easier than with the Flux machines. But to be fair, don't forget that the Glowforge was in beta for about 2 years before backers received their machines (I was one of the early ones) and that was three years ago. The Glowforge is a very polished machine, very easy to use. The Glowforge UI, being web based, is very different than Flux's Beam Studio, which is more of a traditional software package. Some tasks are easier to do with the Glowforge -- such as scoring -- and the engraving feature has more options, such as dithering a dot pattern or line pattern. With that said, I have not yet downloaded the latest beta of Beam Studio and it seems there might be some dithering options now. The Glowforge, BeamBox, and Beamo are all well built machines and work good for all the laser cutting we do, and we do a lot of laser cutting. All the machines have their differences, especially the obvious: the sizes. But in terms of the what they can cut or engrave, everything has been pretty much the same. The 30 watt Beamo has been keeping pace with the 40 watt BeamBox and Glowforge with the materials we commonly use, which is wood and acrylic. Below is an accordion menu. Please click the titles to expand and see their content. Background

They both started on Kickstarter. GlowForge, an American company, had a kickstarter that we decided to pledge. At the time we had no idea what we would use a laser cutter for, but the low price was good enough that we decided to take a risk. Early Bird slots were already taken when we were pledging, but we were able to get the next one or two early pledge levels. The machine was in beta for a long time and lots of folks started to think Glowforge was a scam. The machine was passed around for reviews and made convention appearances. By the time the laser cutter was released a good two, maybe three years had passed. But the GlowForge machine was a work of art -- easy to use, easy to set up, and results were amazing. After years of waiting we were pleased we got a very polished machine. We can only imagine that during those years the folks at Glowforge spent their time optimizing everything about the machine. FLUX is a company based in Taiwan. They got their start with a Kickstarter campaign for the Flux 3D Delta printer. The printer turned out to be a well designed and reliable machine. We pledged for this 3D printer and became pleased with the quality of the machine itself and of the prints. The Kickstarter was handled very well with timely responses and good organization. We also got to see the quality of the customer support. After the Kickstarter ended and everyone got their machines customer support didn't take a back seat. Software was updated quickly and problems were engaged even by the owners themselves. There were rough spots, though (as expected from a company starting out). When customer support started to have problems (mostly long delays) the folks at FLUX took action and updated the support company. With all this we saw that the Flux owners were serious about the company and their reputation. It was also obvious there was a passion involved, especially with the owners taking part in the forum discussions. So when FLUX started a new kickstarter event for a laser cutter, the BeamBox -- a large, 40 watt machine similar in size to the Glowforge -- we decided to support them again. A year later FLUX did another kickstarter campaign for the Beamo -- a much smaller, 30 watt laser cutter. Again we pledged. So we went through three kickstarters for FLUX and one for Glowforge. First Impressions

Without getting into the numbers, the Glowforge is a long, large, mostly plastic, machine. The top and cover is glass. The corners are curved. There is only one single button to control the machine. The rear has an exhaust vent and the power on/off switch. What we bought is the 40 Watt Glowforge Basic. The weight is around 70 lbs and visually it looks good -- like high tech furniture. We get the impression the Glowforge folks are Apple fans as their kickstarter video uses an Apple laptop for demonstrating the software and the ability to engrave the surface of a laptop. The minimalist styling somewhat has that "inspired by Apple" aesthetic. The BeamBox and Beamo are similar looking machines. The BeamBox is much larger than the Beamo, on par with the Glowforge. The shape is more angular and the machine itself is heavy. The body is made of steel and feels much more heavy duty than the Glowforge even though it is also a 40 Watt machine. Where the Glowforge will look well indoors near the kitchen, the BeamBox looks more appropriate in a workshop. The Beamo has a similar appearance to the BeamBox. Similar shape, but a lot smaller; it can fit on an office desk. The Beamo is a 30 Watt machine. Although 30 Watts might not seem like a lot, it is plenty good for the types of projects we do. It cuts all the different woods we use easily, has no problem cutting the acrylics, and no problem cutting plastic, especially the plastic used in 3D printing. Sometimes we engrave on cork and the Beamo is great for that. Sound

I tend to use the Glowforge during working hours as the machine is loud. If at night the noise will disturb neighbors, and I wouldn't be able to hear the TV. Both the Beambox and Beamo are quiet compared to the Glowforge. I can use either of the two FLUX laser cutters at 2 AM without disturbing anyone (as I was doing last night). Airflow / Smells

It seems to me that the Glowforge has better airflow. When cutting wood there tends to be a lot of smoke, and you can see the smoke come off the wood as the laser burns through it. I tend to cut using multiple passes, so I am not using high power on any of my machines. Smoke is noticeable, and the Glowforge does a decent job pulling the smoke away. The Flux machines do have decent airflow too. However, I do notice smoke does tend to circle in areas of the machines longer than I would expect. The Flux machines have an air-assist hose that pushes a stream of air through the laser nozzle. The idea is smoke and fumes can adhere to the laser lens, requiring the lens to be cleaned from time to time. The air-assist helps by keeping smoke and fumes away from the lens. The Glowforge does not have an air-assist, so it is important to maintain the lens by removing it and manually clean it. There is an included tool designed to help with this task. However, these lenses are delicate, easily breakable, easy to scratch. I personally prefer the air-assist instead of having to periodically manually clean the lens -- I have the feeling one day I'm going to drop it. Concerning lingering smells, I think all the machines do a decent job clearing the air, pulling smoke away. The fans seem powerful enough to provide a good, steady stream of air pushing the fumes. The Flux and Glowforge forums do have a lot of topics concerning extra filters and other tips concerning exhausts. UI and Wi-Fi/Connectivity

Web Based: One of the good things about the Glowforge is the UI -- the User Interface. The Glowforge uses a web based UI, it is essentially a web page. There are pros and cons with this, but in terms of just the UI it is easy to control the settings to the machine. There are a lot of nice features the Glowforge comes with and the web based UI is intuitive and easy to learn. The Glowforge is indeed a very polished machine. However, there are some drawbacks, specifically that the UI is web based -- this requires an internet connection. It's not too bad if you have a reliable internet connection, but if you are going to use the machine in a workshop or garage that gets poor Wi-Fi then that may be a problem. There is no way to physically wire the Glowforge to an internet router like can be done with the BeamBox and Beamo. The GlowForge requires Wi-Fi for just about all things. As soon as the GlowForge is turned on the machine will want to home -- do its basic calibration routine -- and homing is the only thing that does not require a wi-fi connection. To do a "print" (as the Glowforge folks like to call it) you have to upload your file to the Glowforge's servers then wait for the UI to change to a different screen showing how your design looks. When you're ready to begin clicking a button/link will send the file to the Glowforge servers for processing your settings. Then the servers will send back toolpath information and your Glowforge will be ready to begin. You will have to then physically press the button on the Glowforge itself to begin laser cutting. Requiring only a wireless connection introduces other aspects that can contribute to down time: server congestion is one of them. We tend to have a steady internet connection on our end, but a few times we can't use our GlowForge because the GlowForge servers are congested, or there's some other thing going on between us and the GlowForge servers. It doesn't happen as often these days as it used to, but it can and did. During the COVID-19 lock down in the US and stay-at-home, we experienced down time with the GlowForge due to not being able to connect to their servers. FLUX uses a different approach for the BeamBox and Beamo. The UI is split between software you keep on your own computer (the Beam Studio) and a convenient touch screen directly on the machines. You install Beam Studio on your own computer. It's got all the tools needed to establish a connection to BeamBox and Beamo, including calibration, setting up the camera, etc. To begin work you simply open an SVG file (GlowForge also uses SVG files (and PDF's if there's a glitch which happens from time-to-time) and arrange the design on the canvas/work area. Different settings, such as laser power/strength and speed/duration is assigned to layers. When you save your layout you save it locally on your computer. The Glowforge UI also works in the same way as the Beam Studio for assigning settings to layers. Both software uses color as a layer. So, for example, red might have one setting, green another setting, and so on. The Flux laser cutters have a touch screen that displays information about the current status of the machine and makes it easy to adjust/tweak a task even while the machine is working. With the touch screen you can change the speed and intensity of the burn and pause the job, or abort the job, all while the laser is doing its thing. Nothing like that exists for the Glowforge. The Glowforge has a single button as the only physical aspect of the UI: If there's a problem the button glows a different color and pulsates. To start a job you have to press the button. But with the BeamBox/Beamo the touch screen has good features for maintenance -- running the water pump, testing the air pump for the air assist, and networking settings. Start and Emergency Stop, Pause

For all of the laser cutters, if a job is currently going on you can stop the job at the machine by lifting the lid. There is a sensor for both brands that will interrupt the job immediately. However, with the GlowForge, lifting the lid will cancel the job. With Beambox/Beamo lifting the lid will pause the job. You can then resume at the menu screen on the machine or at the software. With the Beambox and Beamo, you can start a job at the software too. After setting up the items you want to laser cut, both brands have a button in the software to send the job to the machine, but only the Beambox/Beamo have the ability to begin the laser cut through the software. The GlowForge requires a physical button press on the machine itself to actually begin. Drawing/Text:

When it comes to design, I use 3rd party applications, such as Affinity Designer and SolidWorks. But if you really wanted to, you could use the UI for the laser cutters to draw primitive shapes and text. This feature is standard with Beam Studio, but I believe this is a feature currently on free trial with Glowforge, intended for a premium service. Work Area Layout:

Both brands have a camera under the lid somewhere. The GlowForge has a camera directly under the lid and it is much faster than the Beambox/Beamo to take a snapshot of the work area. But the Beambox/Beamo camera is more accurate once it's calibrated. I don't remember if I had to calibrate the Glowforge's camera during set up. The camera for the Glowforge uses a fish-eye lens and some interesting math to approximate object placements at the extreme edges of the work area. The Beamo/Beambox camera is near the laser nozzle. Requesting a snapshot using the software requires the user to draw an area of interest to take a snapshot in. The laser machine will move the nozzle/camera throughout that area taking a series of thumbnail size photos. The result is not as clean as the GlowForge's camera, but it is more accurate. There is also the tendency with the Beambox to experiences pauses with the camera or to lose the last few snapshots. So far I have not experienced that problem with the Beamo. Heat

Temperature is more of an issue with the Glowforge than with the Flux laser cutters. The Glowforge Basic, which is what I have, can easily become too hot to operate. Typically the Glowforge will have heat issues if the machine internal temperature reaches 75F or greater for the Basic model. The Glowforge Pro has a higher heat tolerance than the Basic. When the machine reaches its tolerance it simply stops the current operation if it's currently doing a job, or simply will not begin a job. Will have to wait for the machine to cool down before it can continue. If the room temperature is already warm, well, that will present another challenge. The Flux machines have a higher heat tolerance. During the Kickstarter campaign I had asked about the heat tolerance. I don't remember the response very much since it was several years ago, but it was much higher than the Glowforge. To this date none of the Flux machines have stopped a job due to heat. Laser Tube

With the Beambox and the Beamo you have to keep the laser tube cooled with distilled water, so have to always make sure the water tank is sufficiently filled. The Glowforge uses an oil and comes already filled. All laser tubes have a shelf-life and will require replacing eventually. With the Beambox and Beamo, you can replace the tube yourself -- Flux has already posted videos how to do this -- and YouTube has a number of videos with people replacing their tubes. The process pretty much is to stop-off the water inside the tube from leaking, replace the tube, then refill with water. Mirror adjustments might be necessary too. With the Glowforge the company encourages to ship the entire machine back to Glowforge for tube replacement, and that costs $500. You can replace the tube yourself, but don't expect help from Glowforge, and if you screw up, you'll have to send the machine back anyway. So if you do get a Glowforge, keep the original shipping box. Glowforge wants folks to ship back in a Glowforge shipping box, and it's a $240 charge to get a new one. Subscription

Some of the GlowForge features are subscription based. The features for using the UI as an editor with drawing and text functions is a premium offering. There's a few more features with the GlowForge that you can not use unless you have a subscription. For me this is worrisome since designs that are going to be laser cut have to be uploaded to the GlowForge servers. With subscriptions being tested for certain features currently going on, what might that become in the future? With GlowForge, every design that is going to be cut is uploaded, then that design stays on the GlowForge servers until you explicitly choose to delete it. For for any one user there is a lot of space being used on the servers and right now that space is unlimited for everyone. But will that always be so? Subscriptions, along with being web-based cloud centric, introduces an element of uncertainty. Folks often voice the concern that being web based anything can happen -- the company can go under, for example -- and you won't be able to use the machine. While this is true, it is more possible for company policies to change, and then suddenly there's restrictions where restrictions did not exist before. Update: The Glowforge UI now has the ability to save your design to your local computer. Flux's Beam Studio is more of a traditional software package that is installed locally on your computer. Your designs are opened within the application and you can make setting adjustments, and save locally. Internet is not required other than to download updates. Likewise, there is no subscription with Beam Studio. Camera

All three machines use a camera for helping with the layout. The Glowforge has a camera mounted under the glass lid. It uses a fish-eye lens to show the entire work area, and fancy math to show items without (much) distortion. It does a decent job concerning accuracy, but the further away an object is from the lens the greater the distortion. Glowforge takes a snapshot of the work area at boot up, and when the lid closes. You can also manually update the snapshot. The Flux machines also uses a camera, but the camera is mounted under the laser nozzle assembly. To see the entire work area, you have to use the camera tool in the Beam Studio software to select the area you want to see. Then the machine will move the camera, scanning the area. You will see the work area as a series of photo snapshots. It does a decent job for layout purposes, and since the camera is directly over the snapshot, it is more accurate than the Glowforge camera, although a bit slower than Glowforge, depending on the size of the area. Other Things

Automatic Focus: The Glowforge has automatic focus. The Beamo also has automatic focus, but this is an extra add-on you purchase separately and connect it yourself. There isn't any automatic focus option for the BeamBox. Rotary Attachment: The Beamo (and BeamBox) also have other add-on's, such as a rotary attachment for engraving cylindrical objects, such as glasses and drink tumblers. Diode Laser Attachment: The Beamo has a diode attachment module. This is something I want to get for my Beamo, the diode laser module. It is less powerful than using a laser tube, but essentially with the diode laser the Beamo does not require the laser tube, the water, etc. No rotary tool or diode attachment with the Glowforge. Other Glowforge models have a pass-through feature, though, for large materials. Multiple Instances

A nice thing about the Glowforge UI being inside a browser window is that I can multiple browser tabs open, each having an instance of the Glowforge UI. I can have the Glowforge do a laser cut in one browser tab while I open another browser tab and begin setting up the next job. To keep things simple I don't open more than two instances. So far with the Beam Studio (Flux) software I haven't been able to run two instances at the same time. Beam Studio can control both machines, but not at the same time. It is fairly easy to switch between between multiple machines, but I have not been able to do a laser cut job on both machines at the same time from one Beam Studio instance. The way I get around this is to have one computer per machine. So, for example, I can have Beam Studio begin a laser job on the BeamBox, then I switch to another computer with Beam Studio and have that control the Beamo. |

DioWarriorsLatest News blog thingy. Archives

May 2024

Categories |

RSS Feed

RSS Feed